Temperature mapping is an important requirement for the storage of pharmaceuticals in a pharmaceutical warehouse, necessary to maintain climatic parameters within specified limits.

A violation of the temperature regime occurs in the presence of zones with maximum temperature fluctuations outside the permissible limits. Performing temperature mapping helps to identify critical areas of the warehouse and monitor them in the future to maintain the established storage regime.

Temperature mapping of a warehouse allows:

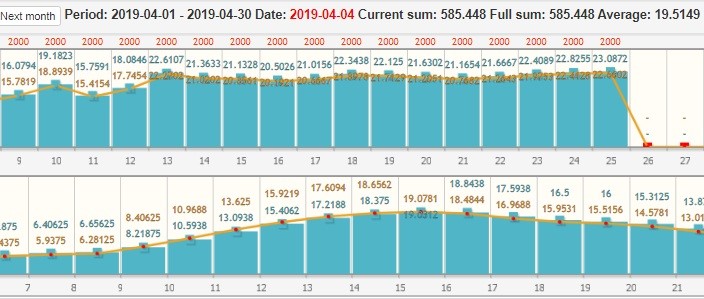

- Reveal the dynamics of temperature over a long period of time.

- Find critical zones with maximum temperature fluctuations.

- Assess the stability of maintaining the temperature regime.

- Evaluate the warehouse with the required requirements.

- Identify areas requiring additional thermal insulation / ventilation.

The sensors are installed at 3 levels in height: above the floor, under the ceiling and between them. Additional near entrance doors, in the loading / unloading area, near ventilation and heating systems.

The D100 radio modules continuously record temperature values at hourly intervals and store them in memory, including the measurement of fluctuations in the outdoor temperature.

When measuring, it is recommended to use the “worst conditions”, including power outages, opening windows, doors, and others.

For various points of the storage, the BALANCE system determines the average, maximum and minimum temperature (humidity) values.

Critical zones with significant temperature differences are identified: from time of day, personnel activity, HVAC system features, loading / unloading and exit zones.

Thermal mapping can be carried out at the following sites:

freezers and refrigerators, refrigerators; warehouses, warehouses and storage containers; trailers, trucks and containers.

The BALANCE system is suitable for temperature control on elevators, granaries, storage of vegetables, fruits, fish, temperature control, humidity, light and gas content in greenhouses.

It is also important to control temperature and gas content in educational and public buildings and premises, where low temperatures lead to a surge in morbidity, and high temperatures lead to cost overruns on heating and ventilation.

An additional advantage of the equipment and software of the BALANCE system is that the system is completely autonomous and can be used when transporting goods in a controlled atmosphere: during transportation in refrigerators, road, rail and sea transportation, in mines and mines.

If GSM communication is available, the data is transmitted at the end of the day, and in the absence of GSM communication, the data can be sent to a local personal computer, or read via GSM or locally upon arrival of a transport (cargo), while recording (logging) can be carried out from several days to one – two months.

In addition to measuring and logging temperature, a number of sensors are available on request: humidity, pressure, illumination, including with division into infrared, red, green, blue, ultraviolet ranges, CO, CO2, CH4 gas sensors, radiation sensors, noise level sensors, voltage level sensors in the power circuit, reserve batteries charge level, wiring fault sensors, power loss and pressure sensors in the water supply network and much more according to your requirements.

In parallel, the BALANCE system can also perform its main function – control of the consumption of energy carriers – electricity, gas, water, heat, fuel, optimizing your costs.

BALANCE mobile application for Android here:

https://play.google.com/store/apps/details?id=com.djv.balance

More information about BALANCE is on the website www.djv-com.org, and we will be glad to hear your suggestions at office@djv-com.net.